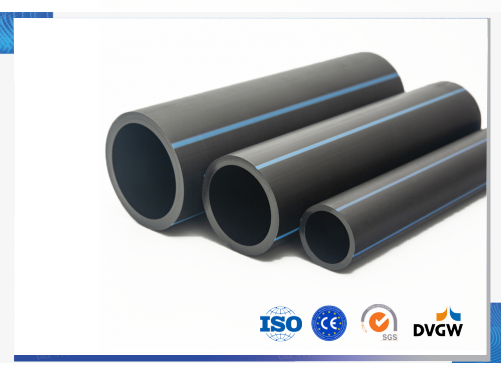

High Quality HDPE Pipe Manufacturer – PE100 Pipes for Water Applications

Diameter Range: DN20–DN2000mm (1/2 inch–80 inch) to meet a variety of project needs.Standard Dimension Ratio (SDR): SDR41, SDR33, SDR26, SDR21, SDR17, SDR13.6, SDR11, SDR9, SDR7.4, SDR6 – ensuring optimal strength and wall thickness.

Pressure Ratings (PN): PN4, PN5, PN6, PN8, PN10, PN12.5, PN16, PN20, PN25, PN32 – suitable for low to high-pressure applications.

Packing & Delivery

Straight Lengths: 11.8m, 11.9m, 5.8m, or 5.9m per piece.

Coils: 100–200m for DN20–90mm for easy transportation and installation.

Lead Time: Fast delivery within 5–10 days depending on order quantity.

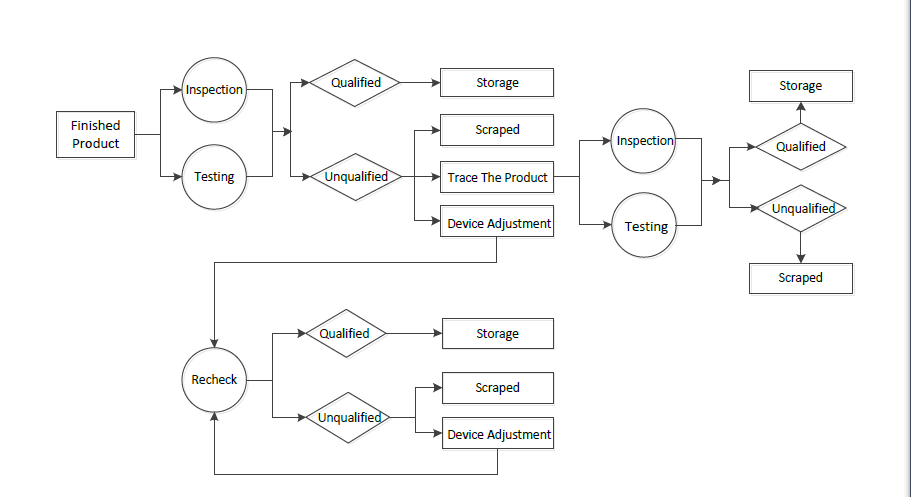

Quality Assurance

2-year warranty, Raw material inspection for quality consistency.

Finished product inspection before shipment.

Third-party inspection available upon client request.

|

Spec(inch) |

Spec(mm) |

Nominal Pressure |

|||||||

|

PN5 |

PN6 |

PN8 |

PN10 |

PN12.5 |

PN16 |

PN20 |

PN25 |

||

|

SDR33 |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

SDR9 |

SDR7.4 |

||

|

Thickness |

Thickness |

Thickness |

Thickness |

Thickness |

Thickness |

Thickness |

Thickness |

||

|

1/4 |

16 |

|

|

|

|

|

|

2.0 |

2.3 |

|

1/2 |

20 |

|

|

|

|

|

2.0 |

2.3 |

3.0 |

|

3/4 |

25 |

|

|

|

|

2.0 |

2.3 |

3.0 |

3.5 |

|

1 |

32 |

|

|

|

2.0 |

2.4 |

3.0 |

3.6 |

4.4 |

|

1 1/4 |

40 |

|

|

2.0 |

2.4 |

3.0 |

3.7 |

4.5 |

5.5 |

|

1 1/2 |

50 |

|

2.0 |

2.4 |

3.0 |

3.7 |

4.6 |

5.6 |

6.9 |

|

2 |

63 |

|

2.5 |

3.0 |

3.8 |

4.7 |

5.8 |

7.1 |

8.6 |

|

2 1/2 |

75 |

|

2.9 |

3.6 |

4.5 |

5.6 |

6.8 |

8.4 |

10.3 |

|

3 |

90 |

|

3.5 |

4.3 |

5.4 |

6.7 |

8.2 |

10.1 |

12.3 |

|

4 |

110 |

|

4.2 |

5.3 |

6.6 |

8.1 |

10.0 |

12.3 |

15.1 |

|

/ |

125 |

|

4.8 |

6.0 |

7.4 |

9.2 |

11.4 |

14.0 |

17.1 |

|

5 |

140 |

|

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

15.7 |

19.2 |

|

6 |

160 |

|

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

17.9 |

21.9 |

|

/ |

180 |

|

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

20.1 |

24.6 |

|

8 |

200 |

|

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

22.4 |

27.4 |

|

/ |

225 |

|

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

25.2 |

30.8 |

|

10 |

250 |

|

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |

27.9 |

34.2 |

|

/ |

280 |

|

10.7 |

13.4 |

16.6 |

20.6 |

25.4 |

31.3 |

38.3 |

|

12 |

315 |

9.7 |

12.1 |

15.0 |

18.7 |

23.2 |

28.6 |

35.2 |

43.1 |

|

14 |

355 |

10.9 |

13.6 |

16.9 |

21.1 |

26.1 |

32.2 |

39.7 |

48.5 |

|

16 |

400 |

12.3 |

15.3 |

19.1 |

23.7 |

29.4 |

36.3 |

44.7 |

54.7 |

|

18 |

450 |

13.8 |

17.2 |

21.5 |

26.7 |

33.1 |

40.9 |

50.3 |

61.5 |

|

20 |

500 |

15.3 |

19.1 |

23.9 |

29.7 |

36.8 |

45.4 |

55.8 |

|

|

22 |

560 |

17.2 |

21.4 |

26.7 |

33.2 |

41.2 |

50.8 |

62.5 |

|

|

24 |

630 |

19.3 |

24.1 |

30.0 |

37.4 |

46.3 |

57.2 |

70.3 |

|

-

Irrigation pipe

-

HDPE Socaet Fittings

-

PP Compression Fittings

-

Electrofusion Fittings

-

PPR Fittings

-

Butt Fusion fittings

|

ITEMS |

HDPE PIPE |

|

MATERIAL |

POLYETHYLENE (PE100) |

|

PRESSURE RATING |

PN5,PN6,PN8,PN10,PN12.5,PN16,PN20,PN25 |

|

SIZE RANGE |

16-630MM |

|

STANDARD |

ISO 4427-2, EN 12201-2, AS/NZS 4130, BS 6920, GB/T 13663. |

|

COLORS |

BLACK, BLUE |

|

CERTIFICATE |

ISO14001, OHSAS18001, ISO9001, CE |

|

CONNECTION |

SOCKET FUSION, BUTT FUSION, ELECTRIC FUSION |

Advantages

-

(1) Non-Toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

-

(2) Corrosion Resistance: resist chemical matters and electron chemical corrosion

-

(3) Low Installation Costs: light weight and ease of installation can reduce installation costs

-

(4) High Flow Capacity: smooth interior walls. Result in low pressure loss and high volume

-

(5) Longevity: more than 50 years under proper use

Applications

-

(1) Municipal water supply

-

(2) Commercial & Residential water supply

-

(3) Industrial Liquids transportation

-

(4) Sewage treatment

-

Address:

No.188 Yaoxin Road , Fengxian District, Shanghai, China

- Tel: +86-21-57405080

- E-mail: sales@rehomepipe.com

- whatsapp: +86 13817660031

English

English  Español

Español